Our Process Header

CELEBRATING

PEOPLE

AND

PLANET

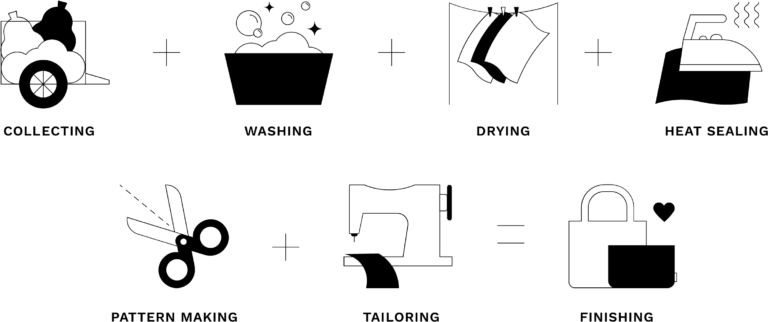

OUR PROCESS

FROM WASTE TO WORTH

01 COLLECTING

Our Waste Collection team, William and Francis, collect plastic and cigarette butts from the streets, local dumps, scrapyards, businesses and households. They pop everything in the trailer, cycle back to the workshop and weigh the collected waste.

02 PREPPING

Our Plastics team, Annia, Matrina and Brenda sort, wash and dry the waste. The team then transform the plastic into durable heat-sealed sheets using irons.

03 FINISHING

Our Tailors, Henry, Noah and Precious make the patterns, cut the materials and create the products by hand, with the help of manual sewing machines. After everyone signs their name on the tag, Henry then personally packs up the order and delivers it to DHL in Mzuzu.

Previous

Next

OUR MATERIALS

NO NEW PLASTIC

We collect plastic and cigarette butts from the streets, local dumps, scrapyards, businesses and households. This waste gets transformed into our stand-out products with the help of some other locally-sourced materials.

We source our striking African wax cotton, chitenje, from multiple suppliers, like Justina and Nophter, at the local Mataifa Market.

Malawians are resourceful people! Many locals salvage and recycle used materials. Smart, one of our suppliers, recycles inner tyre tubes into leather-like strips. We source our old sheet roofing, salvaged seatbelts and scrap metal from people like Smart.

Our hessian and yarn is bought locally from Max. We also collaborate with Chabwela, a local craftsman, to create buckles and buttons using recycled scrap metal.